Neodymium Magnetic System

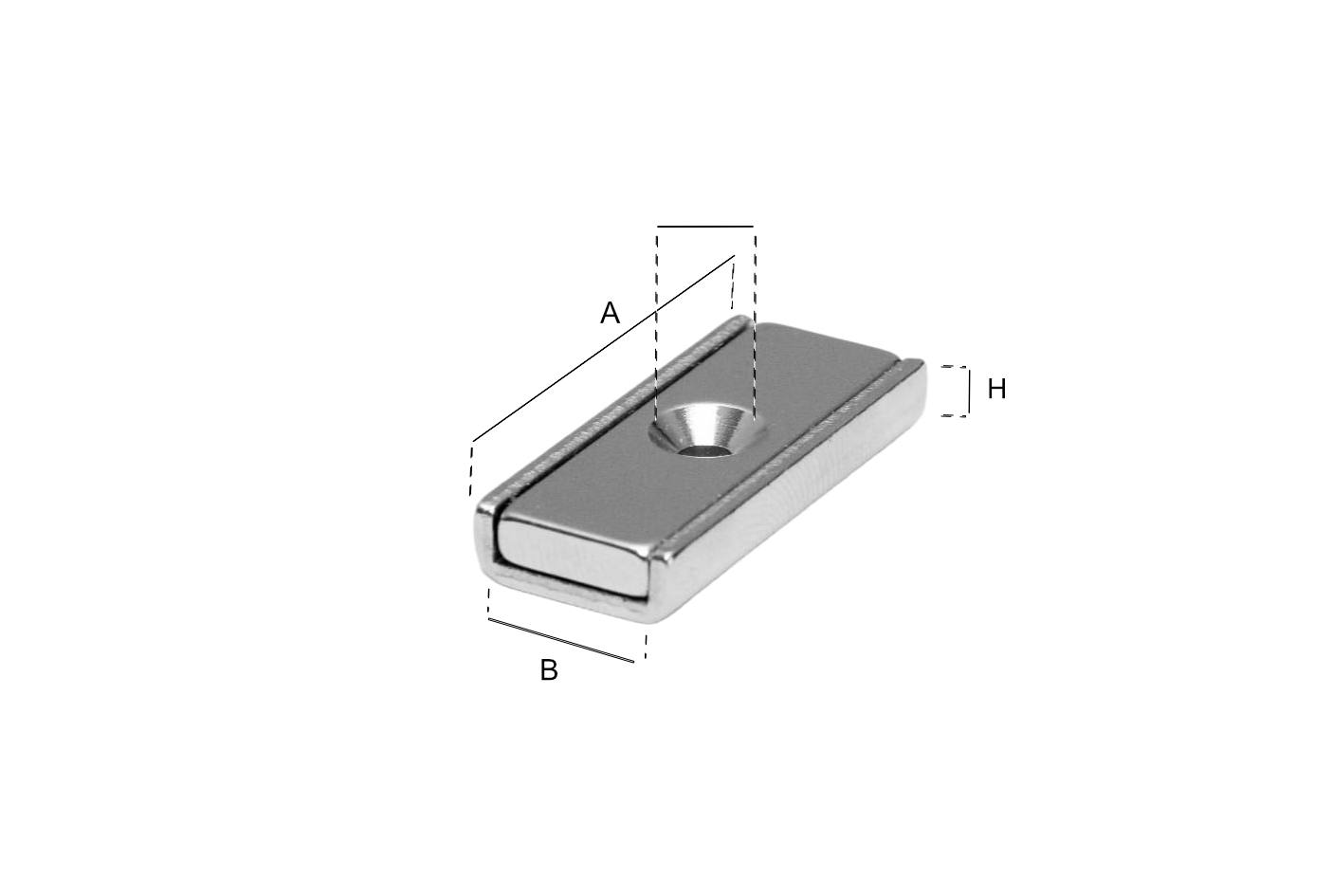

REINFORCED BLOCKS WITH COUNTERSUNK HOLES

(1)_11zon.png)

| CODE | A | B | H | F | STRENGTH KG |

|---|---|---|---|---|---|

| SM80.35NI00.15154F4.5 | 15 | 15 | 4 | 4,5 | 6,00 |

| SM80.35NI00.2013.55M31 | 20 | 13,5 | 5 | 3,2 | 11,50 |

| SM80.35NI00.20204F4 | 20 | 20 | 4 | 4,5 | 11,00 |

| SM80.35NI00.3013.55M31 | 30 | 13,5 | 4 | 3,2 | 19,00 |

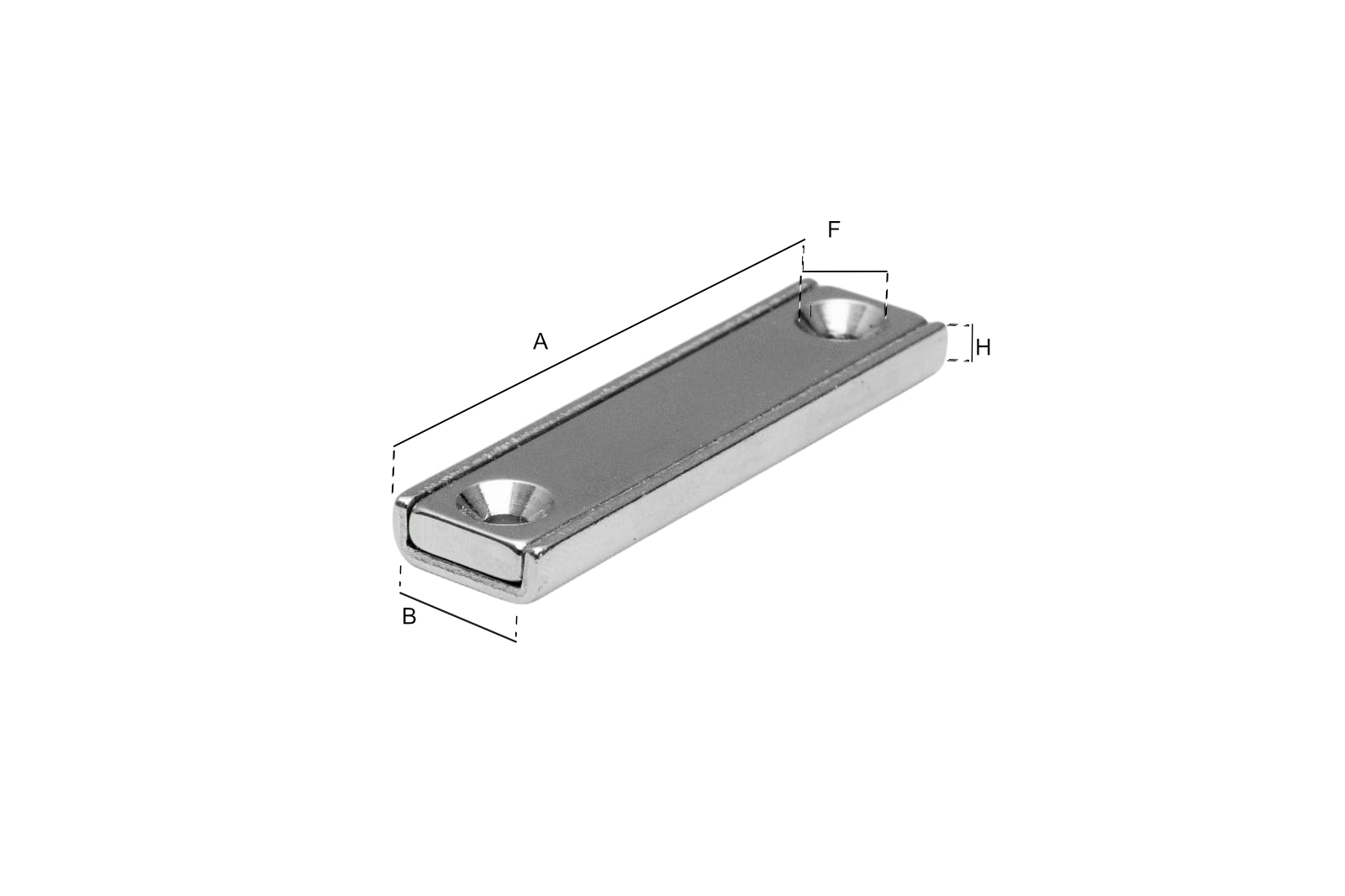

REINFORCED BLOCKS WITH TWO COUNTERSUNK HOLES

| CODE | A | B | H | F | STRENGTH KG |

|---|---|---|---|---|---|

| SM80.35NI00.4013.55M32 | 40 | 13,5 | 5 | 3,2 | 24,00 |

| SM80.35NI00.40204F4.5 | 40 | 20 | 4 | 4,5 | 22,00 |

| SM80.35NI00.5013.55M32 | 50 | 13,5 | 5 | 3,2 | 30,00 |

| SM80.35NI00.6013.55M32 | 60 | 13,5 | 5 | 3,2 | 30,00 |

| SM80.35NI00.60204F4.5 | 60 | 20 | 4 | 4,5 | 30,00 |

| SM80.35NI00.8013.55M32 | 80 | 13,5 | 5 | 3,2 | 43,00 |

| SM80.35NI00.80204F4.5 | 80 | 20 | 4 | 4,5 | 33,00 |

| SM80.35NI00.10013.55M32 | 100 | 13,5 | 5 | 3,2 | 50,00 |

The maximum standard operating temperature is 80 °C.

On request, we can supply magnets capable of operating at higher temperatures, as indicated in the Materials Table.

Many of these sizes are also available in other variants, with different coatings and degrees of magnetization.

The force values given in the tables are the result of dynamometric tests performed with a 10 mm thick iron plate.

Any variations from this standard in the use may change the actual performance of the magnet.

|

It is always recommended to perform specific tests according to your application. |

Request information

For any request or information fill out this form, we will reply as soon as possible.

Fields marked with an asterisk (*) are required.

SM80 with ONE or TWO countersunk holes have been designed to increase both the force and the sturdiness of simple blocks with countersunk hole.

SM80 with ONE or TWO countersunk holes have been designed to increase both the force and the sturdiness of simple blocks with countersunk hole.